Troubleshooting ID-TEK II

Caution do not open side panels without first turning power OFF to the machine.

The faster way to test motors and wiring is to use a multimeter. They are available at hardware stores, Walmart, etc. Click here for a YouTube video on how to use a multimeter.

Check to see if there is power going to feeder.

- Unplug feeder, plug another device (electric drill, etc.) into outlet.

- If it does not work, there is no power at the plug.

On/Off switch is in OFF position.

- Turn switch on.

Faulty sensor probe.

- Clean mixing bowl and sensor probe.

- End of Sensor probe should be 1/4 inch from head of sensor bold and should show at least 1/2 inch of bare wire.

- Open left side panel, disconnect sensor probe.

- If feeder starts, the sensor probe needs to be replaced.

- If feeder does not start, replace Lactek II PC board.

Check fuse.

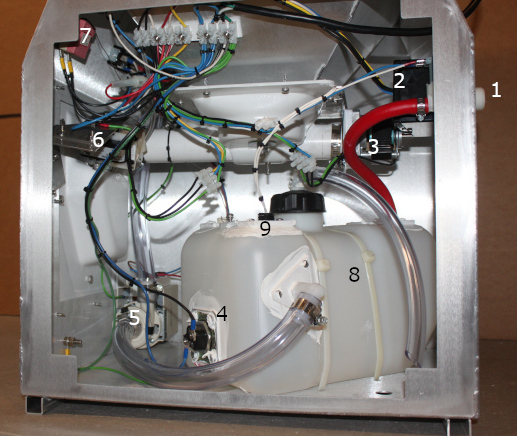

- Open right side panel locate fuse (8).

No water in the mixing bowl, but powder and mixing motor working.

- No water going to feeder.

- Faucet shut off, no water supply, etc.

- Concentration knob turned clockwise all the way.

- Turn concentration knob counter clockwise to open concentration valve.

- Check water valve filter.

- Filter is located inside water valve.

Unplug feeder.

Open left side panel.

Check if water tank is full.

- Water tank not full.

- The water level should be 1 inch to the top of water tank.

- Check water valve filter.

- Filter is located inside water valve.

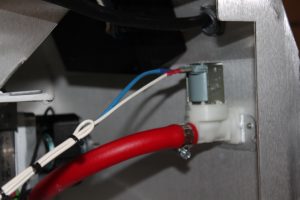

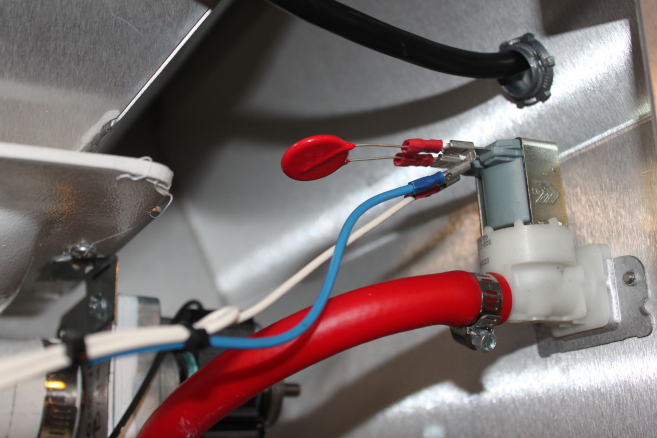

- Check water valve.

- Unplug feeder.

- Open right side panel.

- Disconnect wire from water valve.

- Use a mulitester set it up on resistance. The resistance between the 2 connectors should be 1 kilo ohm.

- If the value is different - replace water valve.

- Check float switch.

- Unplug feeder.

- Remove float from water tank.

- Clean float. Check if float moves freely on shaft.

- Disconnect float wire.

- Use a multitester set on resistance.

- When the float is down the contact should be close (no resistance).

- Move float up the switch and it should open (high resistance).

- If it is a different result, replace float.

Water tank full but no water in the mixing bowl.

- Concentration knob turned clockwise all the way.

- Turn concentration knob counter clockwise to open concentration valve.

- Check for trash in the tubing or in the pump.

- Remove the 3 metal clips to open pump and check if propeller is turning freely.

- Check water pump.

- Disconnect wire and ground wire from pump.

- Use a multitester set on resistance.

- The resistance between the 2 connectors should be 6 ohm.

- It should be an open connection between ground and wire connector.

- If any of these values are different, replace water pump.

Water and/or powder running as soon as you plug in the feeder.

- Bad switch on computer board needs to be repaired.

No powder but water and mix motor are working.

- Powder switch is on rinse.

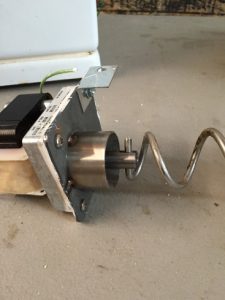

- Check if the auger is disengaged.

- Push auger all the way to the end of the tubing so it hooks back into the connector. When the hopper is full of milk replacer, the milk replacer pushes the auger against the powder motor and keeps the auger in place.

- If there is an object in the milk replacer (paper, cup) it is possible that the auger will become unhooked.

- Object can also prevent the wiper drive to turn freely and prevent the powder motor from turning.

- Check that powder motor is running.

- Turn feeder on.

- If not running:

- Disconnect wires and ground wire from powder.

- Use a mulittester set on resistance.

- The resistance between the 2 black wires should be 9 ohm.

- It should be an open connection between ground and wire connector.

- If any of these values are different replace powder motor.

If powder motor is running but the milk replacer is not coming to the mixing bowl.

- Check if auger coupling is tight on powder motor shaft.

Auger is turning but brings just a little bit of powder to the mixing bowl.

- The wiper wire inside the hopper must be adjusted or bent so it follows the contour of the inside of the hopper. It will prevent the formation of a hole inside the hopper.

Water and/or powder running as soon as you plug in the feeder.

- Back switch on computer board needs to be repaired.

No mixing motor but water and powder are working.

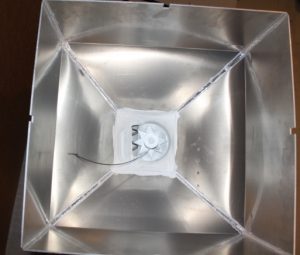

- Check if shaft is turning freely.

- Check if propeller is not touching side of mixing bowl when running.

- Grease mixing motor bearing, if needed.

Check mixing motor

- Disconnect wires and ground wire from mixing motor. Use a multitester set on resistance.

- The resistance between the 2 black wires should be 12 ohm.

- It should be an open connection between ground and wire connector.

- If any of these values are different, replace mixing motor.

Mixing motor running as soon as you plug in the feeder.

- Bad switch on computer board needs to be repaired.

Mixing bowl overflowing all the motors are running.

Mixing bowl overflowing all the motors are running.

- Faulty sensor probe.

- Clean mixing bowl and sensor probe.

- End of sensor probe should be 1/4 inch from head of sensor return and should show at least 1/2 inch of bare wire.

- Open right side panel disconnect sensor probe.

- Connect together two black coming from PC board:

- If feeder does start, the sensor probe needs to be replaced.

- If feeder does not start, replace Lactek PC board.

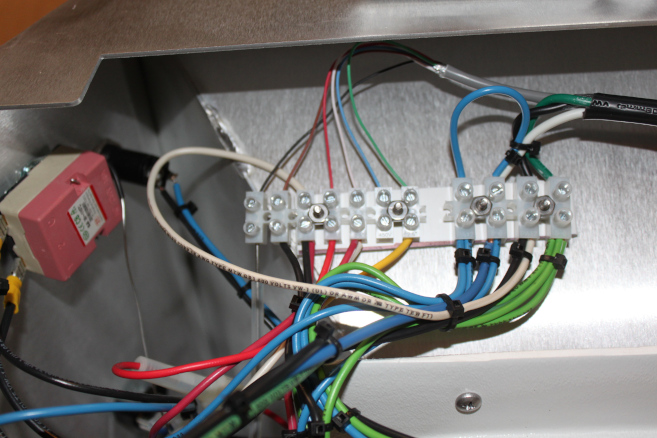

Check for broken wires or loose connection.

Set thermostat at 100ºFahrenheit (40ºCelcius). Red light is on when power is going to the element.

Red light is on but the water is cold.

- Check heating element.

- Unplug feeder.

- Open right side panel.

- Disconnect wire from heating element.

- Use a multitester set on resistance. The resistance between screws should be 10 ohm.

- It should be an open connection between ground and screw.

- In any of these values are different, replace heating element.

Heating element removal

Check thermostat

- Unplug feeder.

- Open left side panel

- Disconnect wires from thermostat.

- Use a multitester set on resistance.

- Put thermostat bulb in cold water.

- Connect tester lead as on picture.

- Turn thermostat knob all the way to off position.

- Switch should be open (high resistance).

- Turn thermostat knob so switch closes (low resistance).

- Warm up thermostat bulb, switch should open when temperature is reached.

- If different result, replace thermostat.

Water is overflowing under or inside the feeder.

- Open right side panel.

- Unplug feeder.

- If water is still running through feeder, replace water valve.

- Check to see if there is trash inside the water valve preventing it from closing.

Check Float switch.

- Remove float from water tank.

- Clean float. Check to see if the float moves freely on shaft.

- Disconnect float wire.

- Use a multimeter set on resistance.

- When the float is down, the contact should be closed (no resistance).

- When the float is up, the switch should be open (high resistance).

- If results are different, replace float.

Reader does not read tag. The reading distance is 2 - 4 inches.

- Reader unplugged at computer box.

- Reader cord damaged.

- Metal next to reader.

- Interference between readers.

- Reads should be at least 6 feet apart.

- Damaged reader.

- Needs to be repaired to replaced.

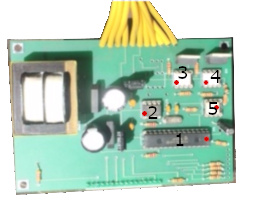

1-Computer Chip

1-Computer Chip

2-Memory Chip

3-Mixing Motor Triac Assembly

4-Powder/Pump Triac Assembly

5-Sensor Probe

Red dot for notch location

- No display.

- Computer unplugged.

- Computer damaged, needs to be repaired or replaced.

- Display on, but showing black squares or gibberish.

- Unplug, wait 30 seconds, plug back in.

- If computer is back to normal:

- Need to add a voltage suppressor on the computer.

- The red disk (varistor) on the water valve needs to be replaced.

- If computer still not working, it needs to be repaired or replaced.

- If computer is back to normal:

- Unplug, wait 30 seconds, plug back in.

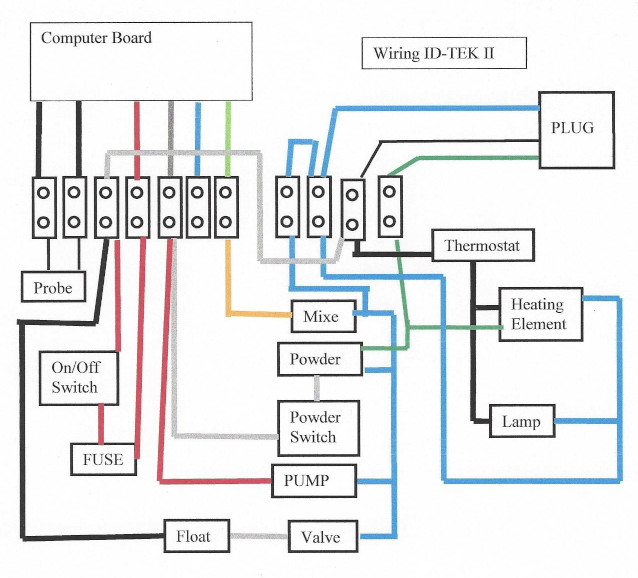

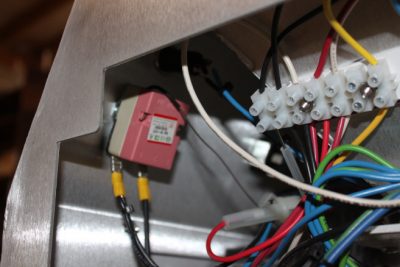

Controller wire color:

Green = Mixing Motor

Blue = Auxiliary Pump

White = powder motor and water pump

Red = hot wire in

Brown = sensor probe

Black = sensor probe